Available coatings

FABRIC

CELLULAR

ELASTOMERIC

POLYURETHANE PVC

RUBBER

SPECIAL

Designed for Performance, Engineered for Excellence

FABRIC

CELLULAR

ELASTOMERIC

POLYURETHANE PVC

RUBBER

SPECIAL

Elatech offers a wide range of materials that can be applied on the back of the belts in order to optimize the performance in even the most complex conveying applications.

The wide range of Elatech coatings can be divided into 6 categories: fabric, foam cell, polyurethane, PVC, rubber and special. Each of these categories is geared to meet the best performance for specific applications. It is also possible to combine coatings to cleats, machining or complex drilling that Elatech realizes with water jet technology.

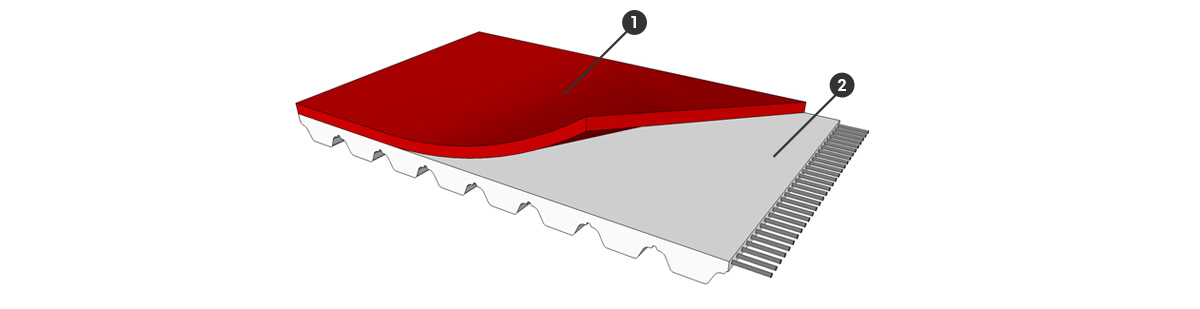

1. Coating

2. Basical belt

The special coating of polyamide fabric applied on the belts, allows a substantial reduction of the friction coefficient. Fabric applied on tooth (PAZ), reduces noise and friction which is key in conveyors with accumulation systems. Also available with antistatic properties.

PAZ: Coating on the teeth. Reduces the coefficient of friction

PAR: Coating on the back. Reduces the coefficient of friction

PAZ-PAR: coating on the teeth and on the back

Coefficient of friction

Polyurethane and foam rubber are materials that can easily be compressed depending on the cellular structure of the material. The main applications are: labeling machines, transportion systems of light and/or delicate materials, glass and paper industry, vacuum conveyors.

The polyurethane is, among all plastic materials and synthetic and natural rubbers, the material offering the best wear resistance. The main applications are those where this feature is required such as industry of woodworking, ceramics, glass. On request, polyurethane coatings in accordance to FDA Regulation are available.

PVC has a high coefficient of friction and a good resistance to acids. Because of its versatility it is used in numerous applications: paper industry, ceramics, woodworking, glass, machines for labeling and packaging.

FDA certification allows the use of the product in the food industry.

Both natural and synthetic rubber coatings are available. Due to their properties (high coefficient of friction and high resistance to temperature) and thanks to the numerous possibilities of processing, these rubbers are used in various applications: paper industry, ceramics, wood processing, glass, labeling and packaging machines

Coatings in different materials and Geometries including Silicones, Chrome Leather, TEZ, Felt, are AVAILABLE for specific applications,